CATEGORY

The crank shaft assembly consists of crank shaft, ring gear, connection rod (with bearing) and the main bearing. The working clearance of bearing is pre-determined by the fitting precision of the installed shaft and the relevant holes.

Shear pin safety valve can be connected in two ways, one is threaded connection, and the second is flange connection.

It is an insurance of mud pump, before the pump working, according to the cylinder and piston specification determines the rated pressure, the safety valve cover off the shear pin on the clipboard into the pin hole.

If the pump head pressure exceeds the rated pressure, shear pin will be cut and mud from the side of the vent valve, play a protective role.

Guider (lower) is installed in the inner chamber of the hydraulic cylinder ,for centering and positioning the suction valve body assembly.

The guider consists of the guide way and the inner sleeve embedded in the guide way.

The material of the guide way is ZG35CrMo, and the inner sleeve is treated by 20CrMnTi carburization and quenching.

Valve rubber mainly adopts polyurethane and nitrile rubber material.

Features: oil resistant, corrosion resistant and wear-resistant.

Working temperature: -35 C -100 C

Work pressure: 40MPa

Normal life: 300 hours of continuous operation

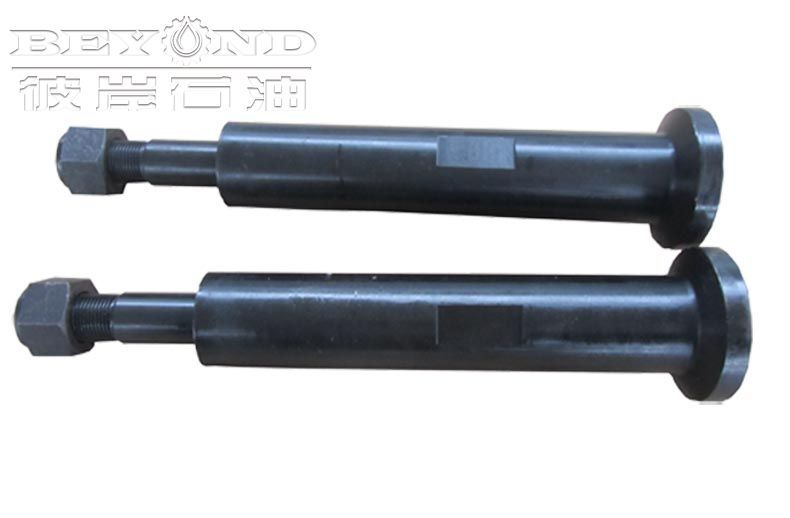

Piston rod is the main parts, which connect mud pump power end and hydraulic end.

The material is 42 CrMo.

We can provide piston rods with various kinds of specifications of F series, 3NB series, PZ series, and others.

Piston assembly is the major part of the mud pump fluid end.

The discharge pressure of mud pump is generated by the up-and-down motion of the piston in the cylinder.

Small piston—high pressure and low flow rate,big piston—low pressure and high flow rate.

Metric pump and inch pump adopts metric piston and inch piston respectively.

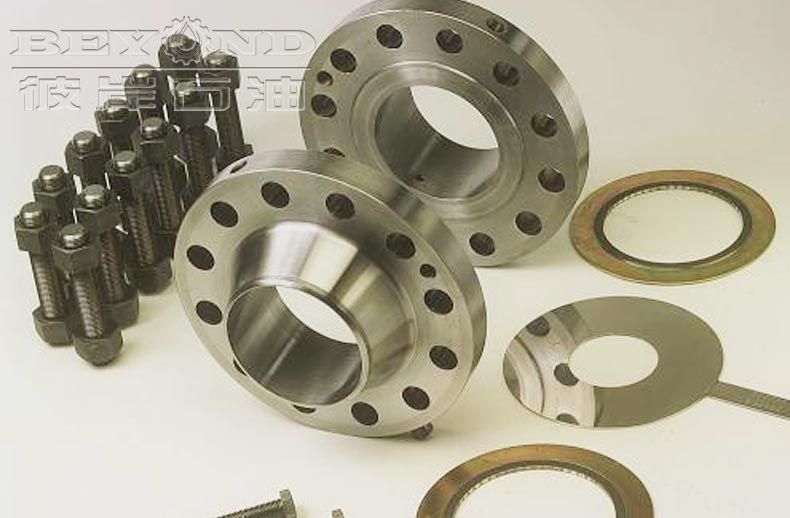

Cylinder head flange is the main parts of drilling mud pump in the system, we can produce all kings of cylinder head flange.

They are exchanged with all major pump models.

The parts are precisely made to meet or exceed OEM specification.

Installation on the discharge line of the mud pump can balance the peak of high pressure fluid pressure of the mud pump, stabilize the pressure, reduce the loss and ensure the safety, and make the mud pump achieve the best effect of inhalation.

The valve assembly consists of the valve and valve seat.

Valve and valve seat are made of one-piece premium forged alloy steel, and follow the manufacturing process specification directly to assure the good finish, accurate size.