11

2025

-

04

Deep interpretation: BEYOND The core competitiveness of the water well drilling rig

Author:

Deep interpretation: BEYOND The core competitiveness of the water well drilling rig

As a strategic core product of BEYOND Company, water well drilling RIGS have successfully served drilling projects in many countries and regions around the world with their excellent engineering performance and highly customized design concepts.In order to enrich project experience and technology accumulation, we have carried out perfect engineer training to ensure that we can provide customers with more professional technical support. For complex and variable geological conditions, we provide professional technical evaluation and personalized configuration solutions to ensure that each unit can achieve optimal drilling efficiency and cost control. The following will analyze the core competitiveness of BEYOND water well drilling rig.

Drill tower

Rig material:Q355B high-strength welded seamless square pipe construction, greater torsional resistance and vertical load, and they are equipped with secondary runways and retractable internal RIGS for structural welding.

Lifting cylinder: thickening cylinder diameter and rod diameter, lifting force up to 40 tons, improve the ability to escape stuck drilling

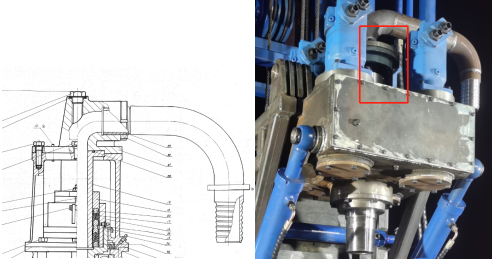

Hydraulic power head

With four hydraulic motor design, more torque and Unique sealing technology to seal mud and air.Hydraulic drill adopts hydraulic transmission system (oil pump - valve bank - motor closed loop control), and realizes stepless speed regulation through progressive pressure loading, eliminating the traditional kelly structure. Its advantage is that the rod change efficiency is significantly improved (single rod replacement time ≤2 minutes), but limited by the system pressure threshold, the output torque is relatively small, recommended drilling diameter ≤311mm, more suitable for medium and soft formation operations.

Rotary table

1. With large torque, the torque can reach 20000NM and the maximum aperture can reach 2000MM.

2. Simple structure, not easy to damage

3. Low power consumption

Note that the factors that affect the drilling aperture are:

(1) The torsional performance of the rig determines the material and structure of the rig;

(2) The torque of the rotating device (turntable or power head);

(3) The flow of air compressor or mud pump

To ensure that we provide you with accurate water well drilling rig configuration solutions and quotations, please provide the following key operating parameters:

1. Target drilling depth (meters)

2. Designed drilling diameter (mm)

Our engineering team will customize the most optimized equipment selection solution and economic benefit analysis report for you within 24 hours based on the technical parameters you provide.

Previous page