18

2025

-

08

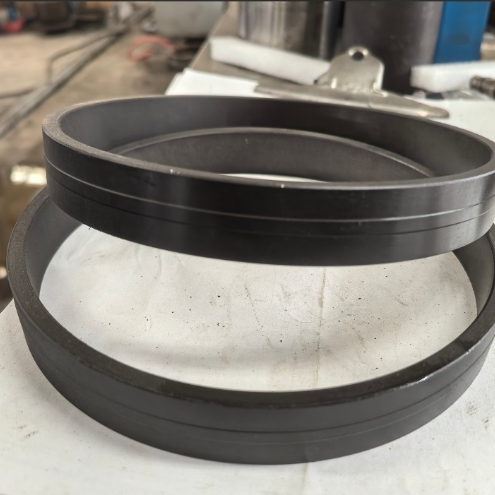

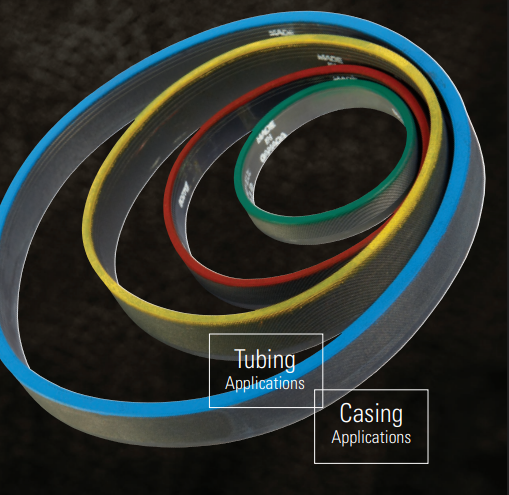

Multi-Lobe Torque (MLT) Rings

Author:

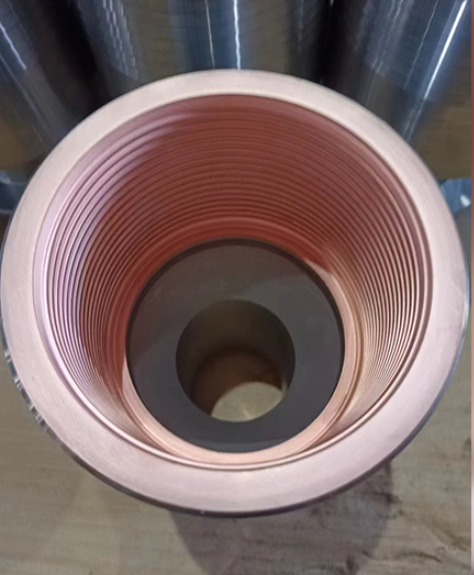

Multi-Lobe Torque (MLT) Rings

The oil casing thread torque ring is a precision pipe fitting used in the center of the oil casing coupling.

Features:

1. Diverse Sizes: Torque rings are available in a variety of sizes to accommodate different tubing and casing specifications.

2. High-Quality Materials: They are typically made of high-quality materials that meet standards such as API Spec 5CT, ensuring durability in harsh environments.

3. Easy Installation: Torque rings can be easily installed into tubing and casing couplings using specialized tools, such as a pneumatic wrench inserted into an installation tool or a tapping tool bar.

Advantages

1. Improved Torque Capacity: Torque rings significantly enhance the torque capacity of casing drilling threads, helping to prevent thread deformation and damage.

2. Enhanced Sealing Performance: Torque rings provide an axial metal-to-metal seal to complement the thread seal, thereby improving the sealing performance of the connection.

3. Reduced Cost: Compared to airtight special threads, the use of torque rings is more economical, helping to reduce overall costs.

Applications

Torque rings are primarily used in oil casing couplings to connect two pipes and ensure a strong and leak-tight joint. They are widely used in oil production, refining, and chemical industries, playing a particularly important role in drilling casing connections.

Principle

The torque ring utilizes its unique structure and material properties to create a strong and leak-tight connection at the oil casing joint. When properly installed in the coupling, the torque ring fills the gap between the two pipe ends, providing a smooth transition and preventing eddy currents from forming in the joint. Furthermore, the torque ring protects the connecting threads from corrosive substances such as hydrogen sulfide, extending the service life of the casing.

Functions

1. Gap Filling: The torque ring fills the gaps in the coupling, preventing fluid turbulence in the coupling and reducing erosion and corrosion on the joint.

2. Thread Protection: The torque ring effectively protects the connecting threads from corrosive substances such as hydrogen sulfide, extending the service life of the threads.

3. Strength Enhancement: The use of the torque ring enhances the structural strength of the connection and improves the torque bearing capacity of the casing drilling threads.

4. Sealing: The torque ring provides an axial metal-to-metal seal, ensuring the sealing performance of the connection and preventing fluid leakage.

Next page

Next page